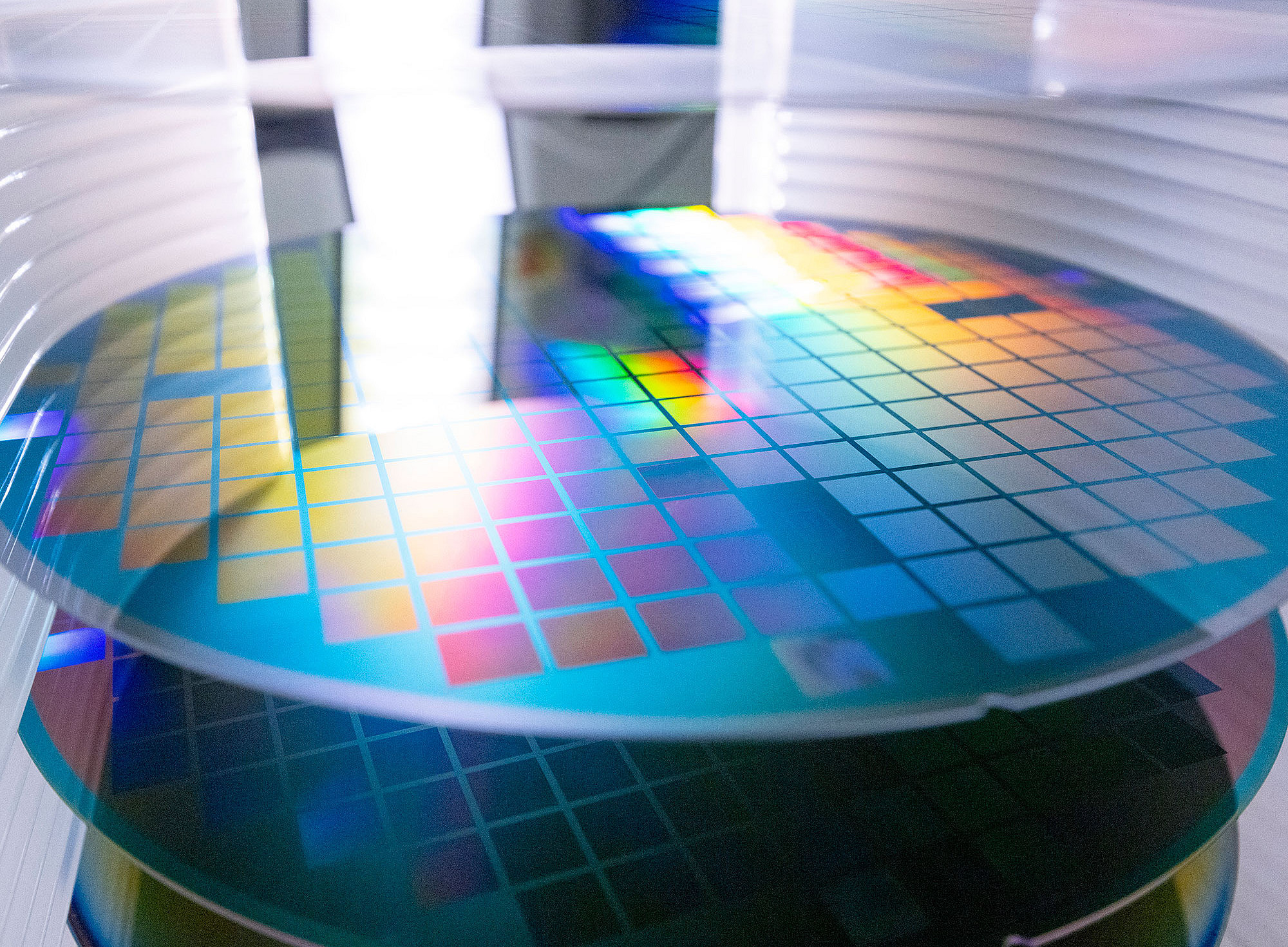

Semiconductors are the backbones of all electronic devices, as they possess the property of conducting and inducting electricity. They are prominently used for the production of integrated circuit chips. In the industrial production process of integrated circuits, plasma etching is widely used. This process involves patterning the semiconductor wafer material through a chemical reaction using halogens such as sulfur hexafluoride (SF₆), tetrafluoromethane (CF₄), trifluoromethane (CHF₃), or octafluorocyclobutane (C₄F₈). However, this method poses significant environmental and health risks. The goal of the “HaloFreeEtch” project is to replace halogens in etching processes for silicon and silicon dioxide with more sustainable alternatives.

“At the Department of Environmental Systems Sciences at the University of Graz, we develop tools that support environmental and social sustainability decisions during the early stages of process and product design,” explains Rupert Baumgartner, head of the Christian Doppler Laboratory for Sustainable Product Management in a Circular Economy. For environmentally friendly semiconductor manufacturing, such decisions concern, among other things, the selection of suitable chemicals and the development of effective etching methods. “These are evaluated and identified using comprehensive lifecycle data and subsequent environmental impact assessments,” says Saumya Sadhu, who is doing research in the project for her doctoral thesis.

Simulations are used to plan and continuously improve industrial etching processes. However, environmental aspects have not been taken into account so far. This is set to change. “We will develop optimisation tools that our partners in the “HaloFreeEtch” project can then integrate into their process simulations,” explains Baumgartner. With this project, his research group will further strengthen its profile in sustainability assessments and sustainable process design. “HaloFreeEtch” complements ongoing projects in high-tech applications, such as batteries for electric vehicles, including new recycling technologies and electrochemical production processes.

“HaloFreeEtch” is a four-year project involving renowned European research and industry partners. The project is coordinated by Jörg Schuster from TU Chemnitz. Rupert Baumgartner is leading the team at the University of Graz. “HaloFreeEtch” is funded with € 3.9 million as part of the Horizon Europe research programme. The University of Graz’s share is € 476,750.